Responsible procurement practices

Sustainable Supply Chain Management Goal

Primax values the CSR of its suppliers. In order to practice the sustainable supply chain management, Primax reviewed its supplier management system comprehensively in terms of sustainability in 2023 . In addition to revising theinternal supplier management procedures, it also clarified the ESG management requirements of suppliers. It will work with its supplier partners to continue improving the compliance management, respond to the climate change and develop in-depth cooperation projects. Supplier partners are of essence forPrimax to move toward sustainability. In line with the ESG goals, such as SDG17 Partnerships and SDG 12 Responsible Production and Consumption, Primax continues to strengthen the sustainability of the supply chain and avoid internal business risks, while it also strives to mitigate the external risks over the societyand the environment, and seize market opportunities proactively.

Types of Supply Chain and Disruption Risk Control Suppliers' Profiles

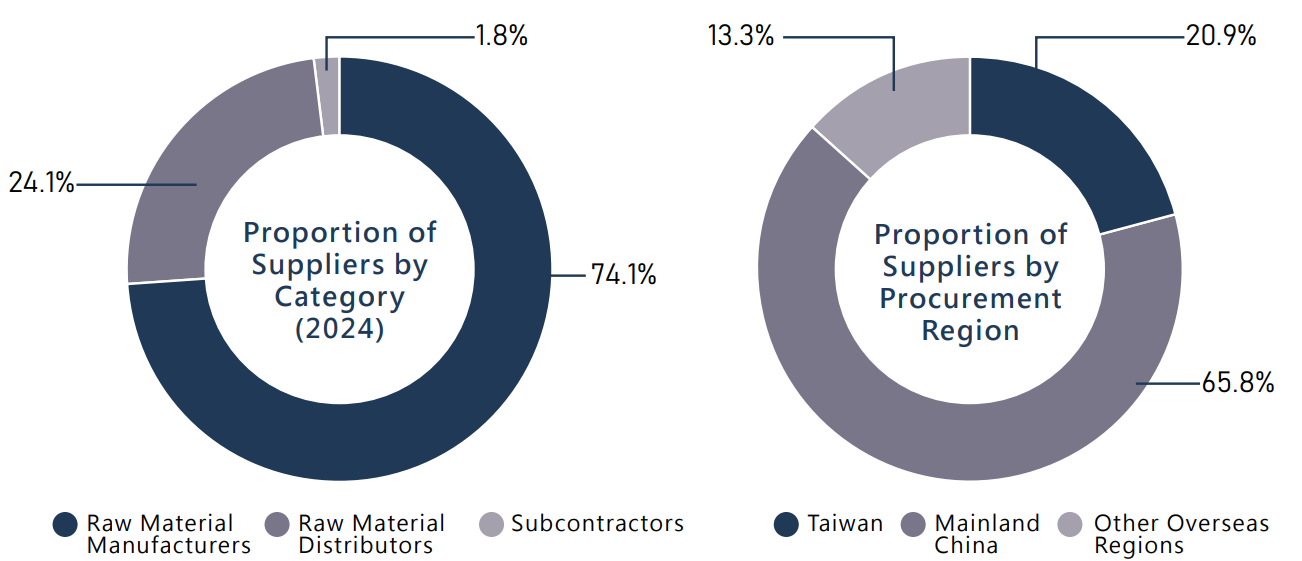

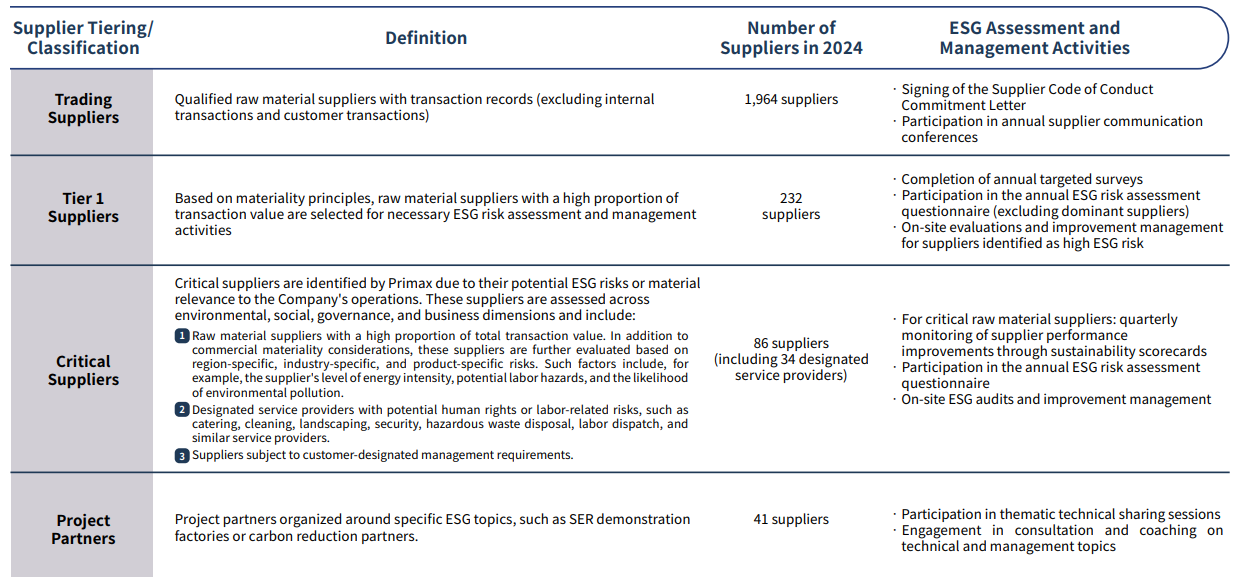

Primax Group's products are primarily designed for use with desktop computers, notebook computers, tablets, and mobile phones. The product portfolio includes keyboards, mice, keyboard modules, touchpad modules, high-speed docking stations, gaming devices, creator peripherals, and wireless charging solutions, with keyboards and mice being the main sales drivers. The supply chain covers a wide range of raw materials, including ICs, printed circuit boards, electronic components, plastic parts, metal parts, and packaging materials. Primax collaborates with 1,964 raw material suppliers worldwide, comprising 1,498 raw material manufacturers, 433 electronic component and raw material distributors, and 33 subcontractors. From a regional perspective, there are 280 suppliers in Taiwan, 1,325 in Mainland China and Hong Kong, and 359 in other overseas locations. In 2024, the total transaction value amounted to approximately NT$39,865 million.

Primax Group promotes localized procurement and short-chain arrangements based on the locations of its manufacturing facilities. For each product line, the Company assesses whether to implement authorized stockpiling and safety stock strategies, taking into account the characteristics of critical components and the lead time required for material preparation. To manage critical materials, short-term measures include internal inventory reallocation mechanisms to address supply disruption risks caused by unforeseeable events. In the long term, Primax has established second-source procurement strategies to diversify the risks associated with reliance on a single supplier, thereby strengthening overall supply chain resilience.

In China, the Company's main production base, the proportion of localized procurement has reached 69.2%, surpassing the internal management target of 65%. At another key production site, the newly established facility in Thailand, the Company is adopting various approaches to progressively increase the proportion of localized procurement each year, as the local supply chain is not yet sufficiently mature to fully support localization.

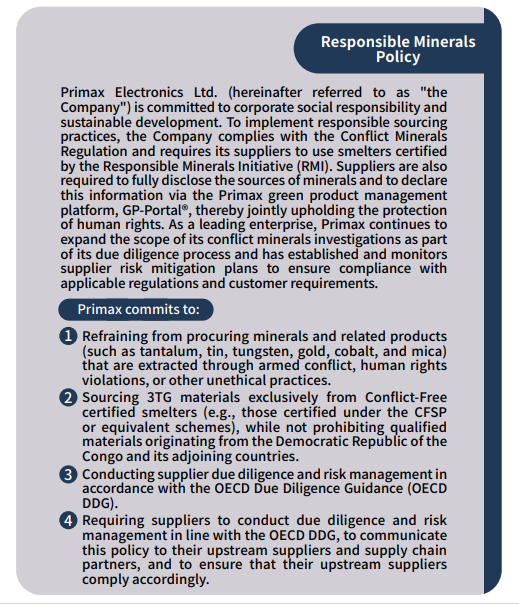

Conflict minerals management and due diligence

Since 2012, Primax has explicitly complied with the Conflict Minerals Regulation, prohibiting the use and procurement of conflict metals (such as tantalum, tin, gold, and tungsten) sourced from conflict-affected regions of the Democratic Republic of the Congo. The Company requires all suppliers to commit to responsible sourcing of minerals and strives to ensure that minerals used in its products (including tantalum, tin, gold, and tungsten) do not contribute to funding armed conflict. This policy has been incorporated as a mandatory requirement in supplier procurement management and product design. Suppliers utilizing conflict metals are required to disclose smelter information and declare it through the Primax green product management platform, GP-Portal®.【For more detailed information, please refer to "2024 Primax Conflict Minerals Report"】

Furthermore, as the electric vehicle industry has rapidly expanded, the applications of rechargeable batteries have also increased significantly. Accordingly, since 2020, Primax Group has required suppliers to disclose information related to the use of cobalt. Our current disclosure scope covers cobalt refiners and recyclers; facilities engaged solely in the production of battery cathodes, alloys, or ceramics are considered downstream entities and are therefore not classified as refiners.

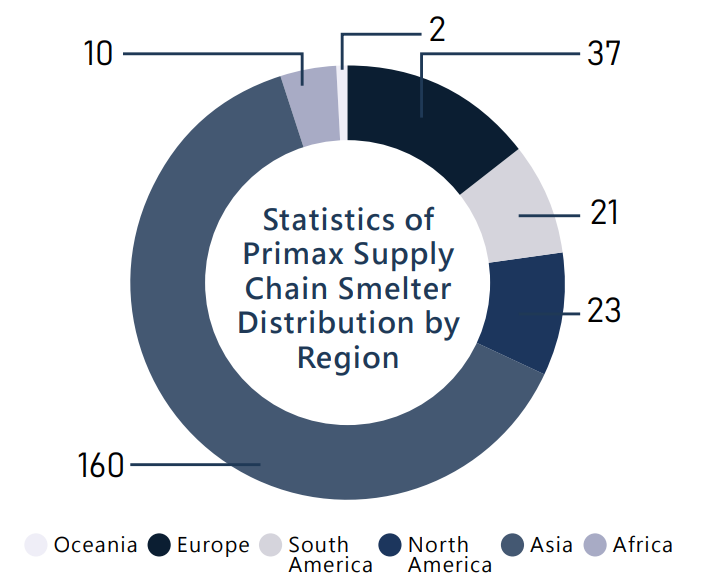

According to statistics on smelter disclosure within our supply chain in 2024, suppliers declared a total of 253 smelters. Among them, gold accounted for the largest number, with 88 smelters, followed by tin (61), cobalt (38), tantalum (34), and tungsten (32). All smelter sources and their countries of distribution, as shown below, are traceable.

In the course of its investigations, Primax references the list of qualified 3TG smelters established by the Responsible Minerals Initiative (RMI) and requires suppliers to use only smelters certified by the RMI. In addition, we regularly cross-check our records against the latest smelter lists to ensure that all materials in use comply with current requirements. In 2024, among the smelters utilized, 31 were removed from the qualified list due to failing to pass the RMI's audit. In response, we immediately launched a supply chain investigation and required suppliers to verify the smelter usage status of their upstream material manufacturers to ensure that no disqualified smelters would be inadvertently used.

At the same time, Primax also adheres to the OECD Due Diligence Guidance for Responsible Supply Chains of Minerals from Conflict-Affected and High-Risk Areas, identifying risks within the Company's supply chain and conducting risk assessments in accordance with the supply chain policy standards and due diligence recommendations outlined in Annex II of the Guidance. In 2024, a total of 301 suppliers underwent conflict minerals management and due diligence risk identification and assessment.

Supplier due diligence

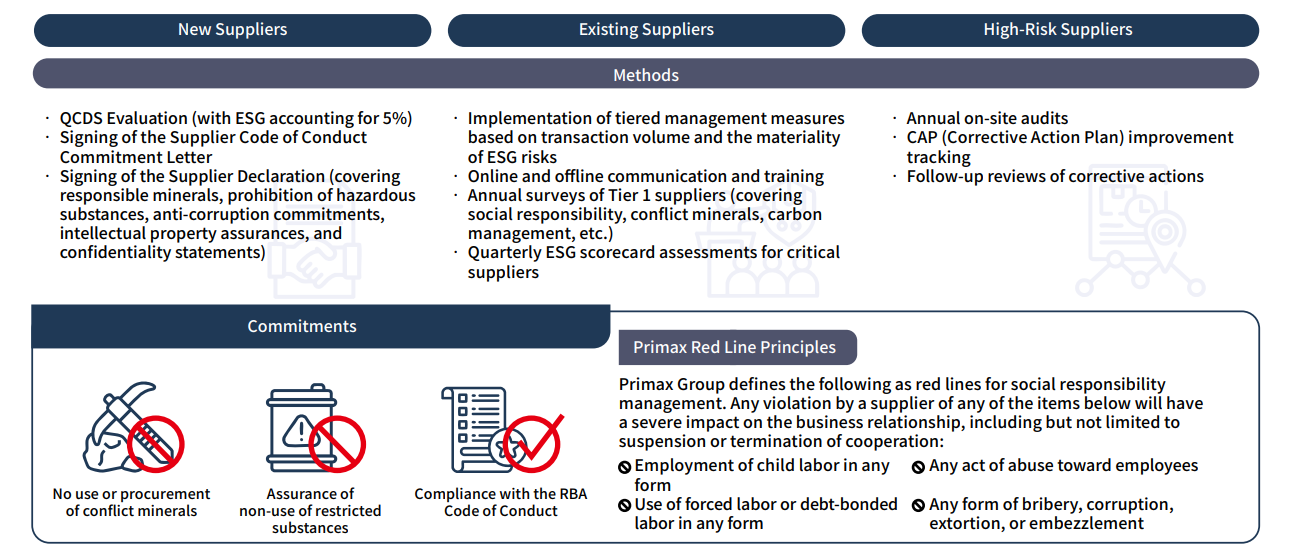

Primax Group practices responsible procurement management and requires suppliers to commit to compliance with applicable local laws and industry codes of conduct to protect the legitimate rights and interests of employees. To further standardize responsible sourcing practices, Primax Group has established the Supplier Code of Conduct. This Code is formulated based on conventions of the International Labour Organization (ILO), the Responsible Business Alliance (RBA), other international labor and human rights conventions, recognized social responsibility management systems (such as ISO 45001 and ISO 14001), and customer requirements regarding labor rights, environmental protection and occupational health and safety, conflict minerals management, and business ethics. It applies to all suppliers of Primax Group and its subsidiaries.

In fulfilling its corporate responsibility for social and environmental management, Primax not only implements internal policies prohibiting child labor and forced labor but also conducts personnel identification during recruitment and periodic internal audits to prevent such practices. The Company strictly requires all selected and managed suppliers to comply with relevant laws and the RBA provisions prohibiting child labor.

Regarding integrity commitments, Primax stipulates that suppliers and their employees must faithfully conduct all commercial transactions, including but not limited to the procurement of materials, project contracting, subcontracted processing, equipment transfer, disposal of obsolete materials, transportation and customs clearance, labor dispatch, and outsourcing arrangements. Should any active or passive conduct occur that undermines procurement discipline, suppliers and relevant stakeholders are required to immediately report such matters to the following designated Primax Group contact point, via letter or e-mail, using their real name and providing contact details, along with accurate information or supporting evidence. Primax will notify relevant internal departments to evaluate and respond to any received correspondence or messages, while maintaining open communication and positive engagement. Suppliers and related stakeholders should not be concerned about retaliation or adverse consequences. (Professional Ethics Reporting Mailbox: This email address is being protected from spambots. You need JavaScript enabled to view it.)

At the end of 2023, Primax issued the first edition of the Supplier Code of Conduct and launched the signature process. All suppliers with transactions in that year and expected to continue transactions in the future, as well as new suppliers, were required to sign a commitment letter declaring their adherence to the RBA (Responsible Business Alliance) Code of Conduct and compliance with related requirements. In 2024, the signature rate of the Supplier Code of Conduct Commitment Letters among trading suppliers reached 87.2%. Moving forward, the Company will continue engaging with suppliers required to sign in order to further increase the signing rate among trading partners.

Signing the Supplier Code of Conduct Commitment Letter is a mandatory requirement for all new suppliers. All new suppliers must pass evaluations on quality, cost, delivery, service, and ESG performance before they can be qualified as formal suppliers. For special suppliers, including dominant international players and customer-designated vendors, environmental and social responsibility declarations are reviewed by Primax through due diligence of their publicly disclosed sustainability reports or equivalent documents. Alternatively, such suppliers may be approved following a comprehensive risk assessment and special authorization by management in order to be included on the Approved Vendor List (AVL). In 2024, a total of 113 new suppliers were onboarded, all of whom completed the supplier assessment process. Among them, 106 completed the signing of the Supplier Code of Conduct, representing a signing rate of 93.8%.

Supplier Sustainability Governance Architecture

With the authorization of the Board of Directors, the ESG Office has been established under the Chairman's Office. The supreme managerial officer, the Chairman, authorized Vice President Chiang, Yan-Ying to serve as the top person in charge.The supply chain sustainability management promotion projectis attended by the social and environmental task forces jointly,also with the procurement unit's collaboration. The relevant progress and results are reported to the Chairman on a quarterly basis. Primax cares about establishment of procurement personnel's capacity in practicing responsible procurement. In2023 , the participants attending the social responsibility internal training included procurement personnel. In 2024 , it also plansto arrange the procurement personnel to undergo the ESG related internal and external training.

Supplier Risk Identification and Hierarchical Management

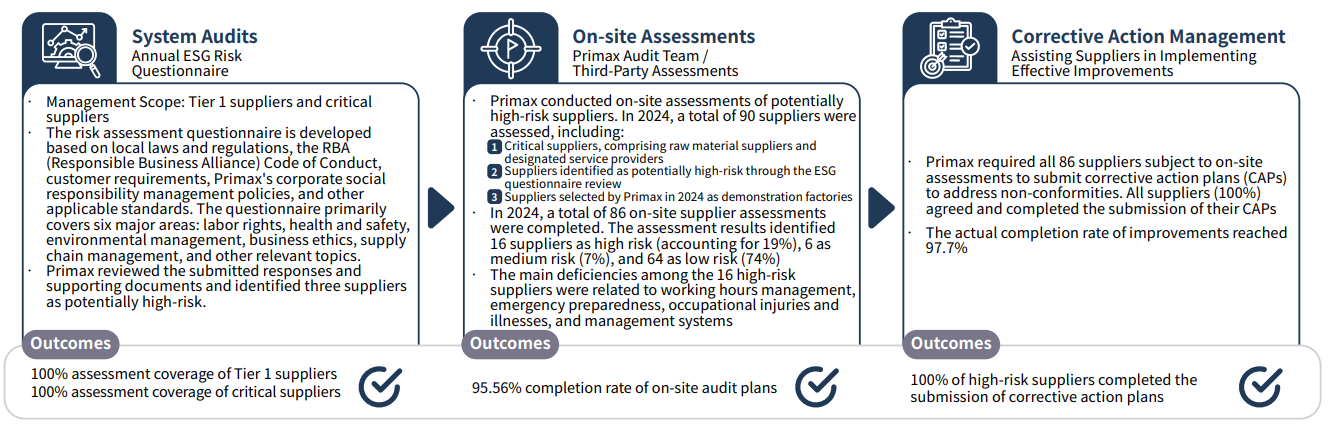

Primax continues to improve the supplier management approach. In 2023, it conducted a comprehensive review on the supplier management system based on the needs for sustainable risk management, in order to define the supplier ESG management plan in terms of investigation and assessment,communication improvement and collaboration. We implementthe supply chain management sustainable development plan toensure that important issues are materialized in the sustainable supply chain management and achieve the establishment of a sustainable supply chain system. In order to improve management efficiency, hierarchical management measuresare adopted, which will be implemented comprehensively from 2024 .

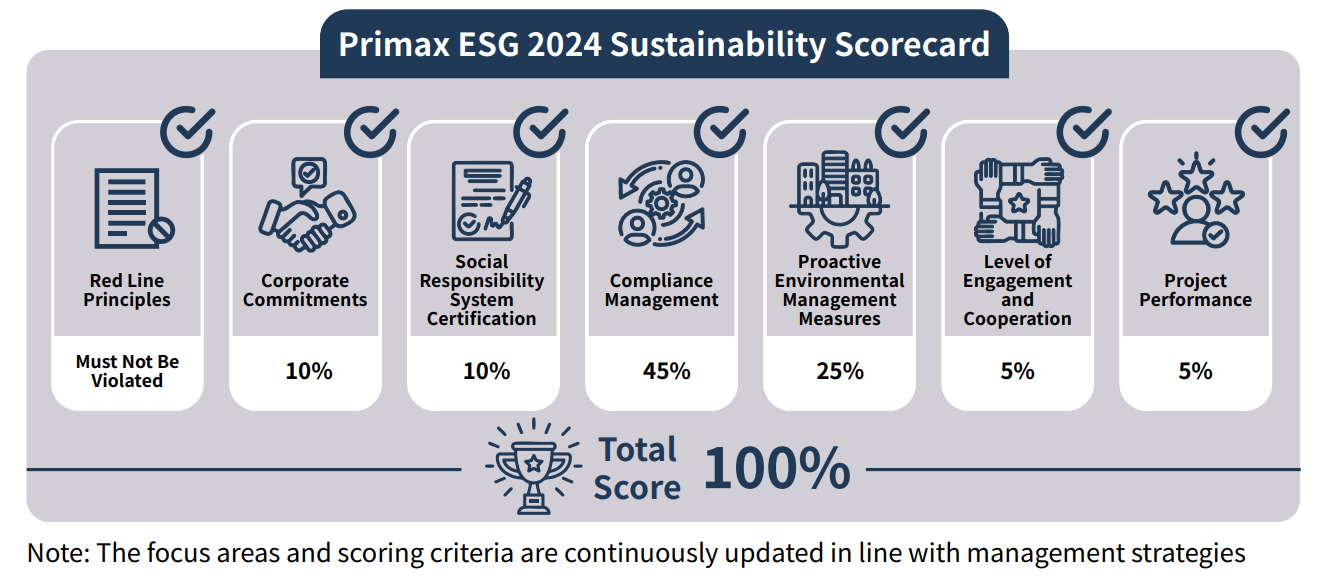

The supplier ESG assessment covers the Supplier Code of Conduct primarily. Specific ESG topics are included to the assessment step by step based on international management trends, the needs for ESG promotion, and the supplier implementation level. First of all, important suppliers are scored based on the indicators referred to in the sustainability scorecard designed with respect to the important suppliers, including the acquisition of the social and environmental responsibility system certificates, compliance management, proactive environmental management measures, and degree of adaptability.

ESG Sustainability Scorecard and Transaction Elimination Mechanism

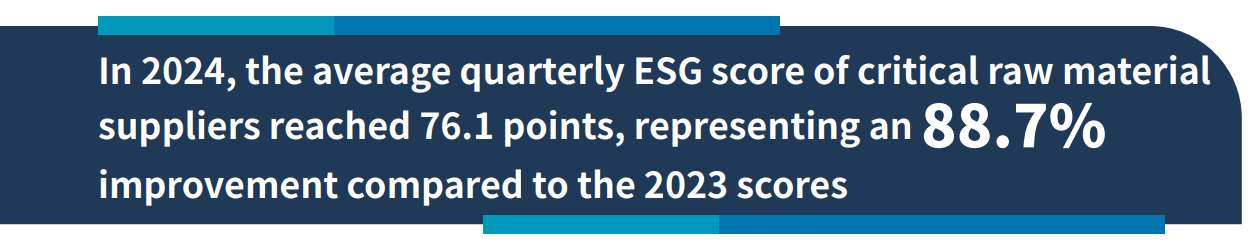

Primax evaluates the ESG performance of critical raw material suppliers each quarter using a sustainability scorecard. Based on the suppliers' ESG score ranges, their quarterly QCDS overall scores may be positively or negatively adjusted by up to 10% weighting. If a critical supplier's final comprehensive performance rating remains at Grade C (below 60 points) for two consecutive quarters, the Company will initiate a process to suspend new project applications with that supplier. Through this robust and iterative mechanism, Primax aims to raise the overall level of sustainable development across the supply chain. Suppliers demonstrating strong performance or exemplary practices will be publicly recognized and invited to share their implementation experiences at the annual supplier communication conference. In addition, Primax promotes greater transparency by disclosing supplier scoring results and rankings to encourage broader sharing of best practices within the industry. The focus areas and weighting of the sustainability scorecard are as follows:

Observations of the assessment scores in 2024 have confirmed that this approach has delivered significant benefits in building the sustainability capabilities of critical suppliers.

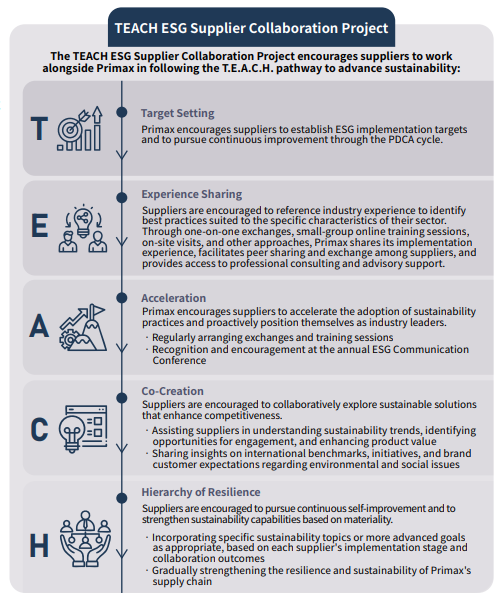

Improvement of Suppliers' Sustainability

In the context of rapidly expanding and deepening sustainability issues, Primax has remained consistently engaged and proactive. Grounded in meeting the expectations of customers and investors, and dedicated to identifying shared sustainable solutions, the Company aims to maximize industry resources and benefits through alliances with industry partners, while supporting the United Nations SDG 17, Partnerships for the Goals. Primax's goal is to work hand in hand with supplier partners through the "TEACH ESG Supplier Collaboration Project." By convening suppliers around specific sustainability topics, the Company strives to create more opportunities and resources for learning, capability building, and advancement, fostering continuous progress together.

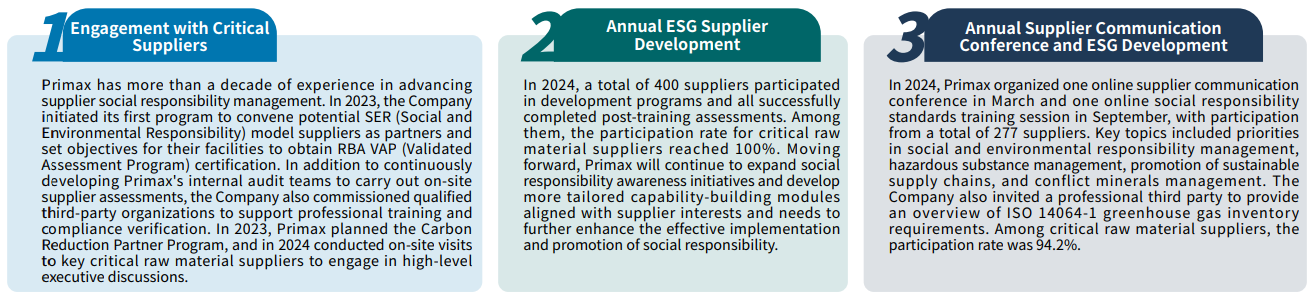

Primax has more than a decade of experience in advancing supplier social responsibility management. In 2023, the Company initiated its first program to convene potential SER (Social and Environmental Responsibility) model suppliers as partners and set objectives for their facilities to obtain RBA VAP (Validated Assessment Program) certification. In addition to continuously developing Primax's internal audit teams to carry out on-site supplier assessments, the Company also commissioned qualified third-party organizations to support professional training and compliance verification. In 2023, Primax planned the Carbon Reduction Partner Program, and in 2024 conducted on-site visits to key critical raw material suppliers to engage in high-level executive discussions.