Wastewater management

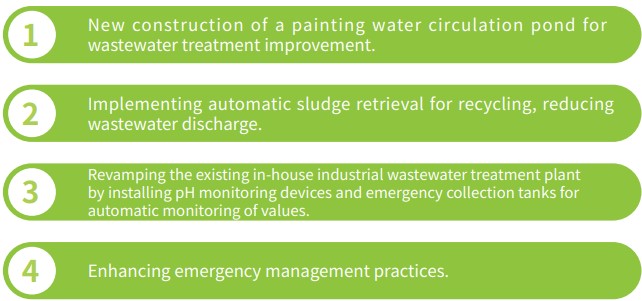

River not only serves as a source of water, but also provides habitat that is vital to creating biodiversity. For this reason, we have devoted part ofour environmental focus to keeping rivers clean. By tracking the volume of water discharged, we are able to ensure effective management of production waste water. In addition to the improvements made in 2016 , the Company also implemented a number of environment-friendly measures this year, such as:

Furthermore, our stringent requirements on hazardous substances in raw materials and consumables exceed international regulations. The discharge of wastewater does not contain harmful substances that would adversely affect receiving bodies of water.

Except for Primax (Dongguan), all other sites in the Group are primarily assembly plants and do not generate industrial wastewater. Industrial wastewater discharged from Primax (Dongguan) fully complies with Guangdong Province's local emission standards, Water Pollutant Discharge Limits. Other sites discharge only domestic and utility wastewater, which is directed into municipal sewer systems or industrial parks in accordance with regulations and does not have significant impacts on local water bodies.

Air pollution management

Air pollution poses adverse impacts on climate, ecosystem, air quality,habitat, agriculture, and human and animal health. Ongoing threats such as deterioration of air quality, ocean acidification, deforestation and public health issues have awoken law makers local and abroad to regulate gas emissions. Forthis reason, we regularly measure emission data that is relevant to causing air pollution, and strive to reduce emission of such gases.

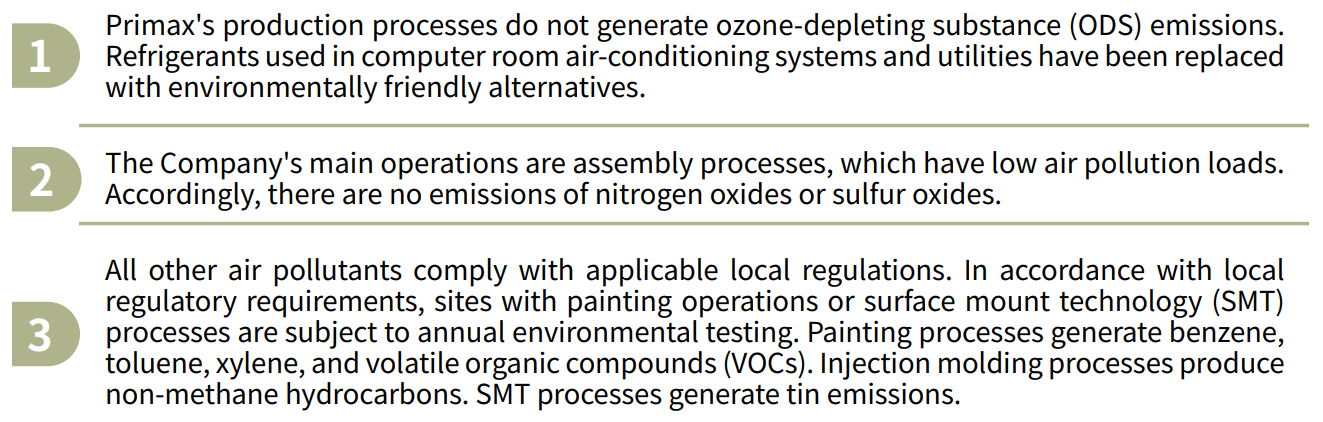

We have summarized 3 main points from the air pollution data:

As for air pollution control, the main air pollutants generated at Primax sites include volatile organic compounds such as benzene, toluene, xylene, total VOCs, non-methane hydrocarbons, lead and its compounds, and tin and its compounds. Accordingly, exhaust treatment processes first involve classifying and collecting organic and particulate emissions in sealed systems, followed by installing appropriate air pollution control equipment to ensure compliance with emission standards. To improve exhaust treatment, UV photolysis units were added to the existing wet scrubber and activated carbon adsorption processes. After going through these three stages of treatment, the plants have effectively enhanced exhaust treatment capabilities. In 2024, 100% of all gaseous emissions from Primax Group complied with regulatory standards. To further control VOC emissions, in addition to ensuring the effectiveness of exhaust treatment equipment, Primax plans to address emissions at the source by developing additional VOC reduction programs at major sites. For production sites subject to VOC regulatory requirements, VOC emissions in 2024 totaled 6,023 kg, a 13.19% reduction compared to 6,938 kg in 2023.

Primax Group air pollutant emission statistics - 2023

|

Plant |

Item |

Benzene |

Toluene and xylene |

Tota VOCs |

Non-methane hydrocarbons |

Tin and related compounds |

|

Primax Chongqing |

Emission concentration (mg/m3) |

/ |

/ |

0.5 |

10.33 |

|

|

Emission (kg) |

/ |

/ |

19.73 |

407.28 |

||

|

Dongguan Primax Liuwu Plant |

Emission concentration (mg/m3) |

/ |

/ |

3.94 |

4.58 |

0.02 |

|

Emission (kg) |

/ |

/ |

1772.25 |

427.42 |

0.66 |

|

|

Primax Kunshan |

Emission concentration (mg/m3) |

1.39 |

||||

|

Emission (kg) |

42.3 |

|||||

|

Primax Thailand |

Emission concentration (mg/m3) |

0.35 |

0.002 |

|||

|

Emission concentration (mg/m3) |

104.4 |

0.58 |

||||

|

Tymphany Dongguan |

Emission concentration (mg/m3) |

0.01 |

3.22 |

0.93 |

0.02 |

|

|

Emission (kg) |

2.77 |

605.26 |

55.73 |

1.13 |

||

|

Tymphany Dongcheng |

Emission concentration (mg/m3) |

/ |

/ |

0.002 |

||

|

Emission (kg) |

/ |

/ |

0.1 |

|||

|

Tymphany Huizhou |

Emission concentration (mg/m3) |

1.27 |

0.001 |

|||

|

Emission (kg) |

669.35 |

0.59 |

||||

|

Tymphany Thailand |

Emission concentration (mg/m3) |

2.23 |

||||

|

Emission (kg) |

618.60 |

|||||

|

Note: 1. Source of data: the 2023 environmental monitoring report of various plant sites. 2. Emission volume = total emission concentration of each emission source * run time. |

||||||

Waste management

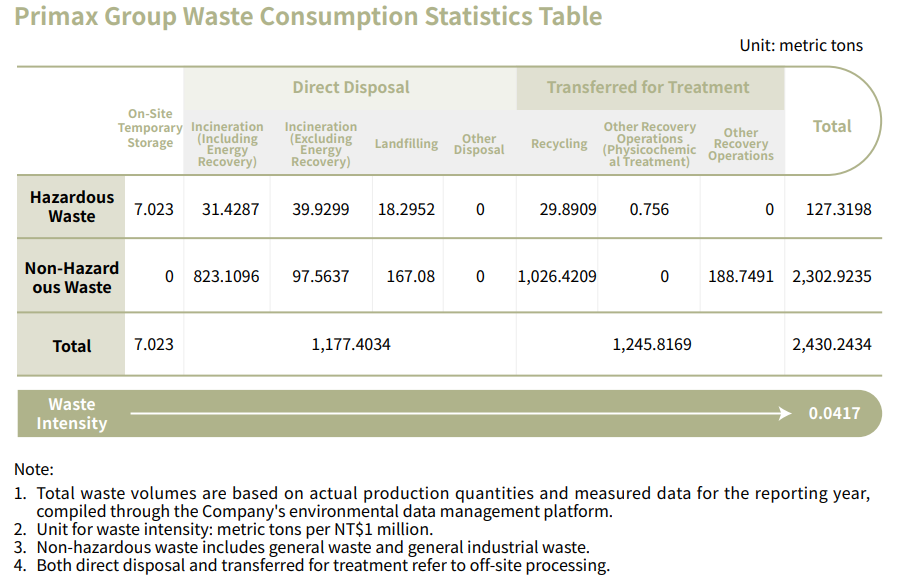

Primax Group's waste is categorized into general waste (including domestic waste) and industrial waste (including hazardous and non-hazardous industrial waste). Industrial waste includes materials such as activated carbon and chemical containers. In 2024, the total volume of waste generated was 2,430.243 metric tons, a reduction of 3.37% compared to the previous year. Waste intensity increased by 0.35% compared to 2023. By disposal method, 1,177.403 metric tons were directly disposed of (comprising 89.65 metric tons of hazardous waste and 1,087.75 metric tons of non-hazardous waste). An additional 1,245.816 metric tons were transferred for treatment (comprising 30.65 metric tons of hazardous waste and 1,215.170 metric tons of non-hazardous waste). For details, please refer to the Primax Group Waste Consumption Statistics Table.

We strive to avoid the premature disposal or landfilling of equipment so that valuable resources can be reused. At the same time, we ensure that these items are recycled appropriately in ways that do not pose risks to employee health or the environment. All hazardous waste is properly stored, managed, and handed over to licensed contractors for compliant treatment. In 2024, Primax Group effectively managed all categories of waste, with no significant waste leakage incidents. All disposal methods fully complied with applicable local regulations.

Environmental protection expenditure

Primax Group leverages its professional expertise to actively pursue process improvements and energy consumption reductions by achieving various assessment targets. These results are supported by our commitment to sustained investment in environmental protection expenditures. Through this approach, we have established ourselves as a model enterprise characterized by high economic benefits, advanced technologies, low resource consumption, minimal environmental pollution, and strong sustainable development capabilities.

Environmental expenditures help assess the effectiveness of environmental measures and provide valuable information for internal cost-benefit analyses. Primax conducts long-term, comprehensive tracking and analysis to ensure that expenditure data supports senior leadership in evaluating the value of complex organizational and technological investments aimed at reducing environmental impacts. At the same time, we continue to develop a comprehensive environmental management accounting system to track information across multiple categories. The focuses include waste treatment, emissions management, remediation costs, and prevention and environmental management expenses. In 2024, the Group's environmental protection expenditures included pollution prevention, resource conservation, waste treatment, and environment-related management costs, totaling NT$69,169,969.

| Item | Cost(NTD) | |

|

1 |

Environmental Protection Equipment and Engineering | 8,788,663 |

| 2 | Management System | 7,692,821 |

| 3 | Human Resources | 47,286,313 |

| 4 | Testing Equipment | 1,973,972 |

| 5 | Energy-Saving Investment | 3,044,199 |

| 6 | Information Management System | 384,000 |

| Total | 69,169,969 |