Primax has applied for joining the RE 100 Initiative on April 29 , 2022 , committed to implementing renewable energy into al loperating locations and proactively setting said renewable energy goals. In addition to implementing energy conservation plans proactively, we have increase the proportion of renewable energy certificates purchased year by year since 2019 and established solar power facilities since 2022 . Meanwhile, we continued to increase the percentage of renewable energy consumption in 2023 to achieve the carbon neutrality goal by 2040 .

Complying with global environmental protocols

Primax Group has developed greenhouse gas, water resource,and energy management procedures in accordance with ISO 14001- Environmental Management System, ISO 14064 - 1 - Greenhouse Gas Inventory, and ISO 14046 - Water Footprint, ISO 50001 - Energy Management System, and have been certified for all of the above systems.

As an electronics manufacturer, energy efficiency, greenhouse gas reduction, wastewater/waste management and green product are all major issues in the environmental category. During the reporting period, we haveset targets for mid- and long-term energy consumption and greenhouse gas reduction, both of which were approved by the top-level management and are being enforced as a major part of the Company's environmental guidelines. Furthermore, we engage third-party institutions to audit our greenhouse gas emission, water footprint, and energy management systemon a regular basis. Due to proper execution of environmental management policies, Primax Group did not violate any environmental laws or receiveany related fines in 2023 .

Primax actively participates in the international initiatives as well as corporate sustainability and climate change events below. In addition to participating in the Carbon Disclosure Project(CDP) Supply Chain Survey to disclose information related to greenhouse gas emissions, energy usage, and water resources, we also conduct internal compliance reviews using the CSA and MSCI Sustainability Questionnaire content to identify areas for improvement and areas where we canmake efforts.

Since 2016 , Primax has began exploring energy conservation solutions at various plant sites,and made adjustments based on the outcome. In response to the opportunities that may arise from climate change, we are actively engaged in low-carbon design and production, establishing rules for products' carbon footprint classification, obtaining carbon labels and carbon reductionlabels. In the recent years, we have worked harder to integrate the automated and information systems, in order to provide more accurate and timely digital information. These efforts not only enhance the corporate image of the Group but also create new business opportunities.

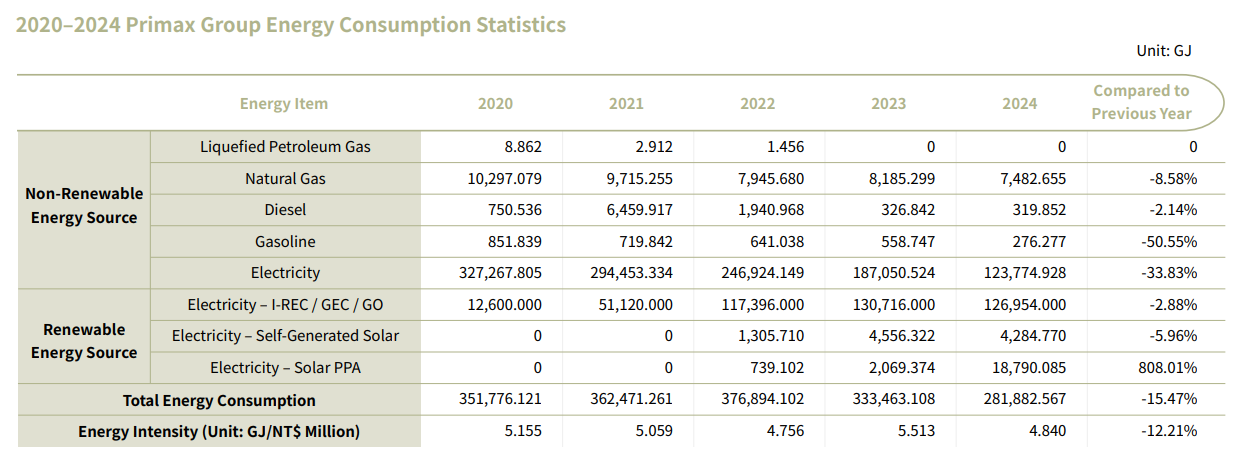

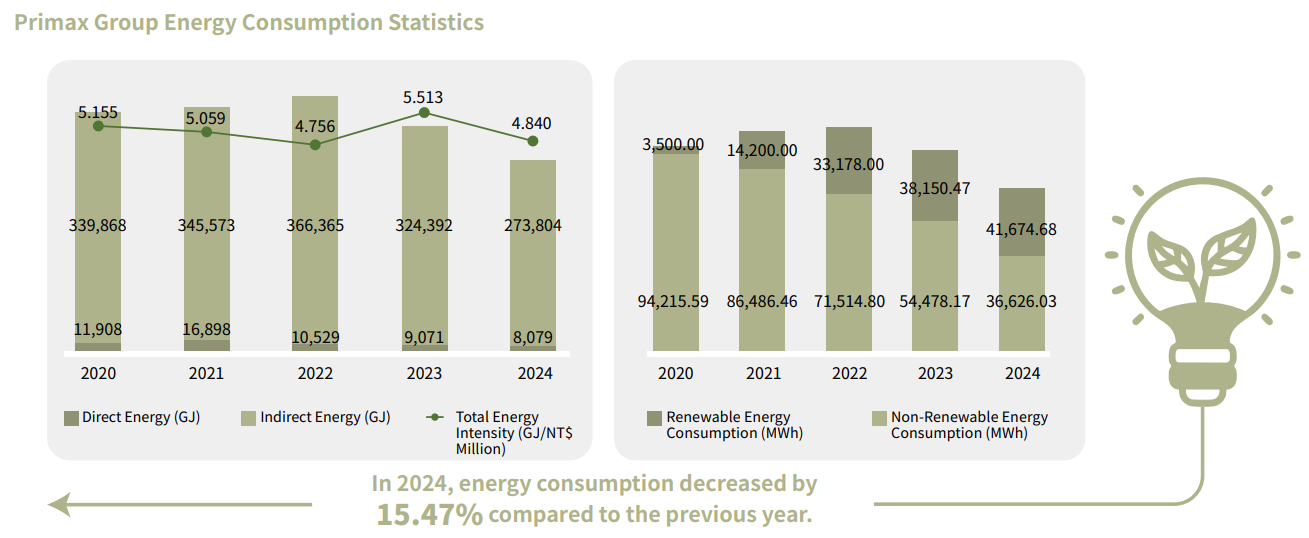

Energy consumption

Making efficient use of energy is key to mitigating climate changes, and is a goal we strive to achieve by continually improving our production procedures. Each year, Primax collects and analyzes data to enhance its existing energy strategies. Primax Group's data on energy consumption is as follows:

Use of Renewable Energy

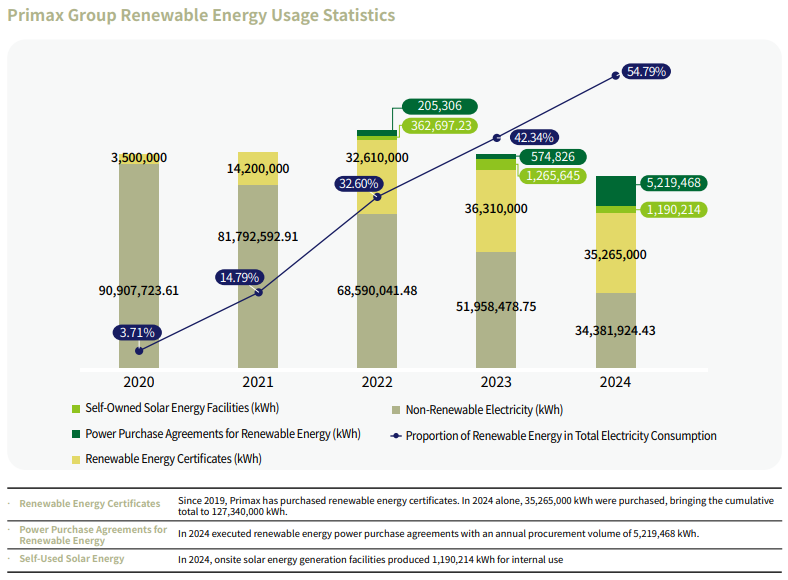

Since 2019 , the Primax Group has been actively promoting a renewable energy utilization plan. This initiative mainly involves purchasing Energy Attribute Certificate (EAC), developing in-house solar power generation facilities, and engaging in Power Purchase Agreements (PPA) for renewable energy procurement to increase the utilization of renewable energy. In April 2022 , Primax joined RE 100and established a target to achieve 100 % renewable energy usage by the year 2040 .

In 2023 , the plant sites of Primax Dongguan, Chongqing and Kunshan,Tymphany Dongguan and Huizhou, Primax Thailand, Tymphany Thailand and Czech purchased renewable energy certificates (GEC and I-REC). Additionally, theplant sites of Primax Dongguan and Chongqing, and Tymphany Huizhou also usesolar power to provide electricity directly.

- Renewable Energy Cartificates: Since 2019, Primax has purchased renewable energy certificates. In 2024 alone, 35,265,000 kWh were purchased, bringing the cumulative total to 127,340,000 kWh.

- Power Purchase Agreements (PPA) for Renewable Energy: In 2024 executed renewable energy power purchase agreements with an annual procurement volume of 5,219,468 kWh.

- Self-Used Solar Energy: In 2024, onsite solar energy generation facilities produced 1,190,214 kWh for internal use.

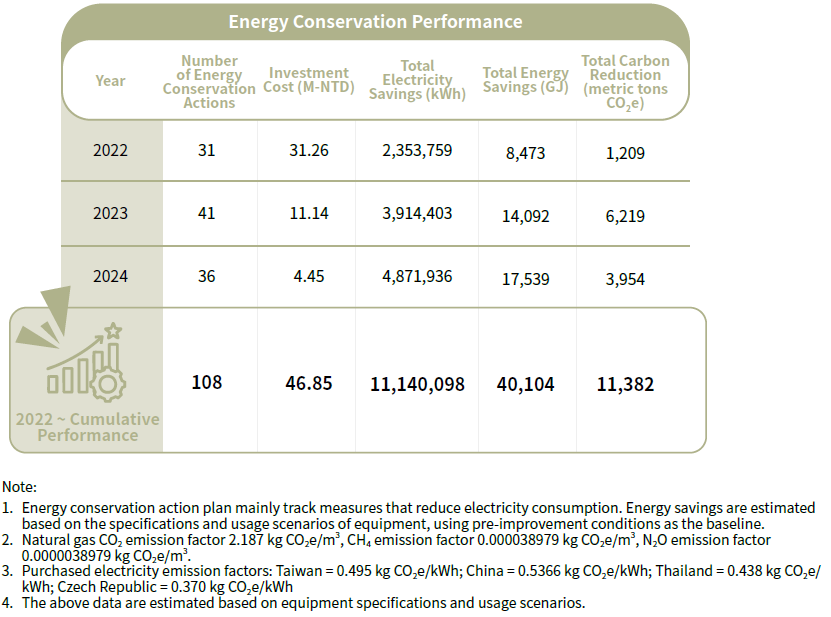

Energy-saving action plans

To enable all operational sites to use energy more efficiently, we explore a variety of energy conservation measures and are committed to building low-energy-consumption facilities. Through systematic replacement of high-energy-consuming equipment, we are dedicated to achieving the ultimate goal of energy-efficient operations. In 2024, specific measures included installing self-owned solar energy facilities, replacing natural gas boilers with air-source heat pump water heaters, adopting behavioral changes in the use of air conditioning and lighting, replacing motors with energy-efficient models, optimizing air compressor utilization, upgrading and improving the efficiency of chiller systems, replacing lighting in factories, warehouses, and outdoor areas with LED or solar streetlights, replacing air compressors with variable-frequency models, and implementing waste heat recovery systems. In 2024, these actions resulted in electricity savings of 4,871,936 kWh, energy savings equivalent to approximately 17,539 GJ, and an estimated reduction of about 3,954 metric tons CO2e.